Eye protection - a must in industry and trades!

Our new developments

Eye protection summarised

What hazards are the eyes exposed to?

The dangers to our eyes can be divided into three categories:

- Optical (UV and IR radiation, glare from light) - suitable protection is provided here by, for example, safety glasses

- Mechanical (impact, foreign bodies) - suitable protection is provided by, for example, safety glasses and full-vision goggles.

- Chemical (acids, alkalis, gases, vapors, fog, smoke) - suitable protection is offered here e.g. by full-vision goggles.

Of course, our own personal behavior plays an incredibly important role; we ourselves are responsible for the protection of our eyes. Only the constant wearing of occupational safety products guarantees protection against the various hazards.

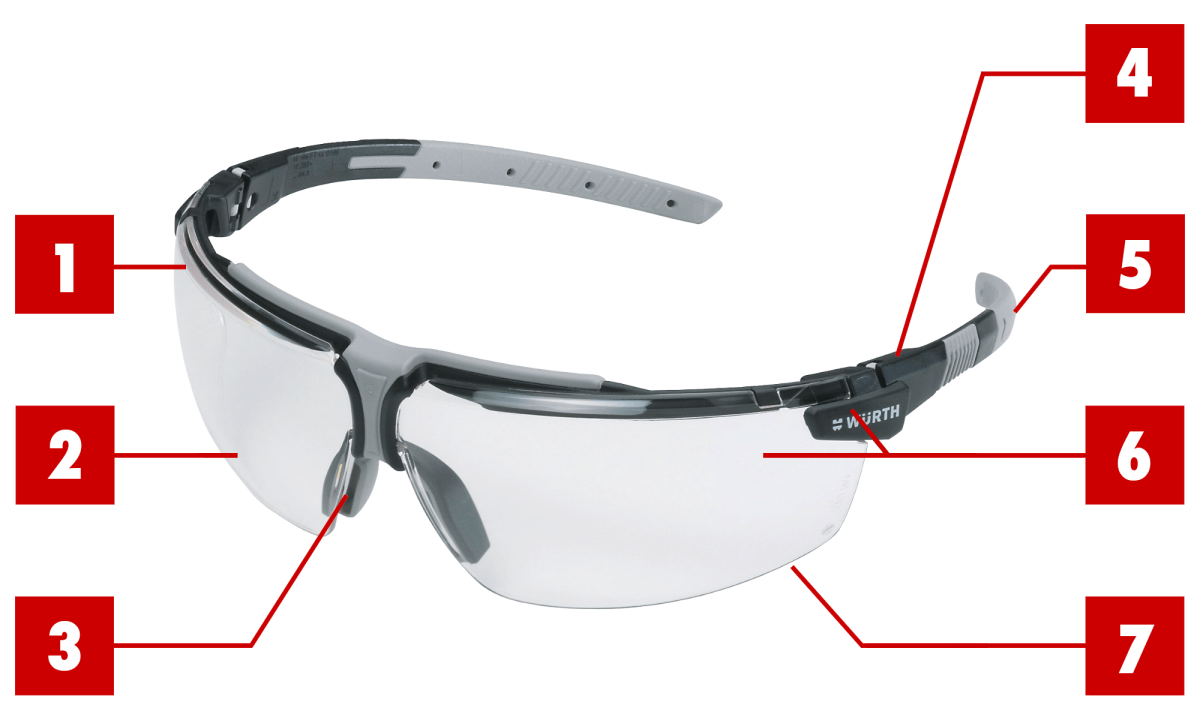

What must safety glasses be able to do?

- In the event of an impact, the safety goggles must not shatter, nothing must penetrate the lens and the goggles must not fall off the head.

- Hot particles or flying sparks must not burn into the frame or lens during work, or even leave visible traces.

- Soft, flexible nose padding for particularly pleasant wearing comfort and a secure fit.

It goes without saying that Würth safety glasses meet these requirements for safety and wearing comfort. In addition, our goggles are characterized by other features that improve wearer acceptance:

- Perfect fit, in that our goggles adapt to the shape of your head.

- Modern, sporty design

- High durability

- Extremely scratch-resistant and permanently fog-free inside thanks to unique coating technology

- 100% UV protection (up to 400 nm) or 99.9% UV protection (up to 380 nm). Usually 380 nm, but 400 nm UV protection is better. This minimal difference is not noticed in everyday life. In the long term, the higher UV protection is essential for health, which can prevent cataracts, for example.

When must eye protection be replaced?

Employees must perform a visual inspection before using their eye protection to check that it is in proper condition. If the eye protection shows signs of damage, it must be replaced immediately. In the case of typical wear and tear, care must be taken to ensure that the necessary visual requirements can still be met.

Unlike eye protection, face protection is intended to holistically protect the wearer's entire face (face, neck and respiratory tract) from hazards such as flying parts (flying sparks), from chemicals or potentially infectious materials. A face shield can be either a visor, a face shield or even full-face goggles with a face shield.

Welding protection

Various hazards such as radiation, heat, spatter, fumes and gases can arise during the different welding processes. In addition, there is a risk of burns and fire in almost all welding processes. Welding protection protects the body against these hazards. That's why Würth has welding protection from head to toe.

Our welding helmets and welding protection caps have been classified according to recommended areas of use. The recommended protection levels are only a guide and correspond to EN 169:2002. The individual sensitivity of the eyes may require a deviation of ± 1.

Tips and Tricks

Ideal for precision work: Cetus® X-treme 65KB

The blue light reduction feature provides protection against harmful blue light radiation, resulting in less eye strain and UV irritation.

View in e-ShopProperly clean and store your eye protection!

- First, rinse off coarse dirt under running water.

- Then clean your safety goggles or face guard with our goggles cleaning cloths.

- When not in use, it is best to keep your safety goggles in a goggles case to protect them from possible damage.

Eye emergency plan

Familiarise yourself with the appropriate conduct in an emergency:

| 1. Determine the contaminant | 2. Select the correct bottle and rinse solution | 3. Begin rinsing | 4. Rinse as directed |

|---|---|---|---|

| Foreign objects e.g. dust, dirt, splinters |

Eye wash solution | Eye wash solution | Rinse until foreign objects have been rinsed out. |

| Acids |

Neutralizing eye wash solution | Eye wash solution | Rinse eyes with neutralising eye solution for 2 minutes until the bottle is empty. Continue rinsing with the eye rinse solution until medical treatment is sought. |

| Alkaline |

Neutralizing eye wash solution | Eye wash solution | Rinse eyes with neutralising eye solution for 2 minutes until the bottle is empty. Continue rinsing with the eye rinse solution until medical treatment is sought. |

| Other chemicals e.g. solvents and oils |

Eye wash solution | Eye wash solution | Rinse eyes until the discomfort can no longer be felt. Continue rinsing with the eye rinse solution until medical treatment is sought. |

Important! For all contaminants, the eye should be rinsed with a gentle, uniform stream. Only squeeze the eye rinse bottle slightly during the rinsing process. Medical advice should be sought for any eye injury or contamination. Rinsing should be continued en route to hospital/doctor.

In-house development of the safety goggles

Würth maximises quality assurance, testing and cost-efficiency by developing protective eyewear in-house.

The new protective eyewear from Würth is designed for practical use as well as aesthetic function. Quality also plays a decisive role.

Our product development process is divided into briefing, creation of sketches, renderings and 3D samples.

We worked closely with designers from Denmark, whose special expertise contributed greatly to this product development. After the designers produced initial sketches and proposals, which were then revised by product managers, the creation of renderings began. This is a process by which three-dimensional objects can be realistically represented with the help of software. Subsequently, these renderings were used to create the first 3D samples of the new protective eyewear using a 3D printer.

3D printing has attracted more and more attention in recent years, especially in industry, and nowadays it is impossible to imagine development and production without it. In this process, liquid material is applied layer by layer by the printer, which then hardens and you already have a finished 3D model in your hands!

The Adolf Würth GmbH & Co. KG collects and processes the personal data provided in the form in order to process the requested request for you. Please note the mandatory fields in the forms. The legal basis for this processing, the absolutely necessary data, is Art. 6 para. 1 lit. b GDPR, implementation of a pre-contractual measure. The processing of data voluntarily provided by you is carried out on the basis of Art. 6 para. 1 lit. f GDPR. Thereafter, processing is permissible which is necessary to safeguard our legitimate interests. Our legitimate interest is to have contact with you, our customers, to improve our consulting quality and to be able to contact you more easily in case of possible queries. The data collected will only be stored by us for as long as is necessary to process your enquiry and to contact you. They are then deleted.

Supplementary data protection information, in particular regarding your rights to information, correction, deletion, restriction of processing, objection and complaint, can be found in our data protection declaration.