New in hand protection

Protective gloves with touchscreen function

Through digitisation and Industry 4.0, touchscreens are already standard in our everyday lives and in many workplaces. Capacitive touchscreens are the most common. To operate these touchscreens, electrically conductive materials are required, meaning standard gloves do not normally function reliably.

This makes touchscreen-compatible gloves the ideal solution for all work areas that require protective gloves to be worn while at the same time requiring the use of touchscreens. They offer an additional benefit in terms of wearer safety as well as protecting sensitive surfaces and workpieces since the gloves do not have to be removed.

How do I determine the appropriate protective glove in the Würth assortment? Look for the touchscreen glove pictogram on the product page!

Find the glove that's right for you:

Protect, clean, maintain. It's all about your skin!

Our skin is our greatest sensory organ. Attuned to mechanical, thermal and chemical stimuli, the skin gives us a variety of vital information about our immediate environment. To make your skin feel comfortable: protect it, clean it and care for it. In order to provide the right support in every situation, our assortment includes everything from basic to specialised products. Dirt has no chance - not even the stubborn kind. Our SKIN LINE skin protection concept works perfectly together, being based on three pillars. The three are distinguished from one another by a colour coding system.

Our skin protection products' performance is rated according to our power rating. The power point system shows you how intensive the effect of each product is, on a scale of 1 to 5.

Olive stones as exfoliants - kind to the skin and the environment

Microplastics in hand cleaners and cosmetics are coming under increasing criticism. The more that enters the environment, especially watercourses and oceans, the more likely it is that the tiny particles will eventually find their way into the stomachs of animals and then into our food chain. That's why olive stones are now used as an environmentally friendly exfoliant in all hand cleaners that are suitable for our SKIN LINE CLEAN dispenser system.

The smooth surface of the olive stone flour has a very gentle effect, feeling very similar on the skin to conventional plastic exfoliants. With our N-Super hand cleaner you can rub your hands and tackle persistent dirt in an environmentally friendly way.

The ABC of protective gloves

Different activities carry different risks to your hands. This is why each glove is assigned to a risk category, defined as follows by the PPE regulation 2016/425:

- Category I: Includes only minor risks, such as superficial mechanical injuries, exposure to mild cleaning agents or hot surfaces whose temperature does not exceed 50°C. An example of a protective glove in this category is the Tricot glove, cotton.

- Category II: Includes risks not covered by Category I or Category III. An example of the protective gloves in this category are our cut protection gloves.

- Category III: Includes only risks that can lead to serious consequences such as death or irreversible health damage. These include, for example, cut injuries caused by hand-guided chain saws or damage caused by environments with an air temperature of 100°C or more. An example of the protective gloves in this category are our Chemical protective gloves.

Protective gloves can be divided into further categories depending on the properties and area of application.

1. General assembly and mechanical work

The coating:

The material and the type of coating significantly influence the properties of gloves with regard to mechanical characteristics (abrasion, penetration etc.), grip, sensitivity, breathability and chemical resistance. The following four coatings are characterised by different properties.

2. Cut protection gloves

Cut protection gloves are primarily intended to protect against injuries caused by cuts. In addition to a high cut resistance, other properties such as good grip, abrasion resistance or heat resistance play an important role depending on the application area.

To ensure that you have the ideal hand protection for your activities, our product selection includes many different cut protection gloves. The characteristics of each model and the differences between them can be found on the e-Shop product pages.

3. Chemical and disposable gloves

Protection against chemicals

Chemical and disposable gloves are designed to protect against chemical risks. An important distinguishing feature of these gloves is their permeation performance. Permeation is the process by which a chemical penetrates the protective glove material on a molecular level. The time between when the chemical first comes into contact with the glove and when it penetrates the material is the breakthrough time and this is expressed as a performance level.

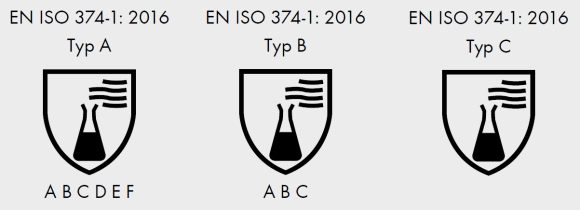

New labelling of chemical protective gloves in accordance with EN ISO 374-1:2016

- Permeation performance type A: At least 6 test chemicals must reach minimum level 2 (>30 minutes)

- Permeation performance type B: At least 3 test chemicals must reach minimum level 2 (>30 minutes)

- Permeation performance type C: At least 1 test chemical must reach minimum level 1 (>10 minutes)

Test chemicals according to EN ISO 374-1:2016:

| Code letter | Test chemical | Code letter | Test chemical | Code letter | Test chemical |

|---|---|---|---|---|---|

| A | Methanol | G | Diethylamine | M | Nitric acid 65 % |

| B | Acetone | H | Tetrahydrofuran | N | Acetic acid 99 % |

| C | Acetonitrile | I | Ethyl acetate | O | Ammonia water 25 % |

| D | Dichloromethane | J | n-heptane | P | Hydrogen peroxide 30 % |

| E | Carbon disulphide | K | Sodium hydroxide 40 % | S | Hydrofluoric acid 40 % |

| F | Toluene | L | Sulphuric acid 96 % | T | Formaldehyde 37 % |

Performance levels against permeation according to EN ISO 374-1:2016:

| Measured breakthrough time | Performance level against permeation (permeation level) |

|---|---|

| < 10 min | 0 |

| > 10 min | 1 |

| > 30 min | 2 |

| > 60 min | 3 |

| > 120 min | 4 |

| > 240 min | 5 |

| > 480 min | 6 |

Protection against microorganisms

New labelling of chemical protective gloves in accordance with EN ISO 374-5:2016:

- Labelling of gloves that protect against bacteria and fungi

- Labelling of gloves that protect against viruses, bacteria and fungi

4. Heat protective gloves

The requirements for heat protective gloves are very diverse. Depending on the application area and environmental conditions, a wide variety of factors must be taken into account to ensure effective protection of the user. Protection against thermal risks is regulated for protective gloves by EN 407-2004. The following test criteria are evaluated. The rating scale ranges from zero to four. A higher performance level means a better level of protection.

- Burning behaviour

- Contact heat

- Convective heat

- Radiant heat

- Exposure to small splashes of molten metal

- Exposure to large amounts of liquid metal

| Test criteria | Rating scale |

|---|---|

| Burning behaviour | 0-4 |

| Contact heat | 0-4 |

| Convective heat | 0-4 |

| Radiant heat | 0-4 |

| Exposure to small splashes of molten metal | 0-4 |

| Exposure to large amounts of liquid metal | 0-4 |

Tips and Tricks

Prevent infections. Wash your hands properly

1. Place hands under running water

2. Use sufficient soap

3. Rub soap into hands for 20-30 seconds

4. Rinse thoroughly

5. Dry hands with a disposable towel

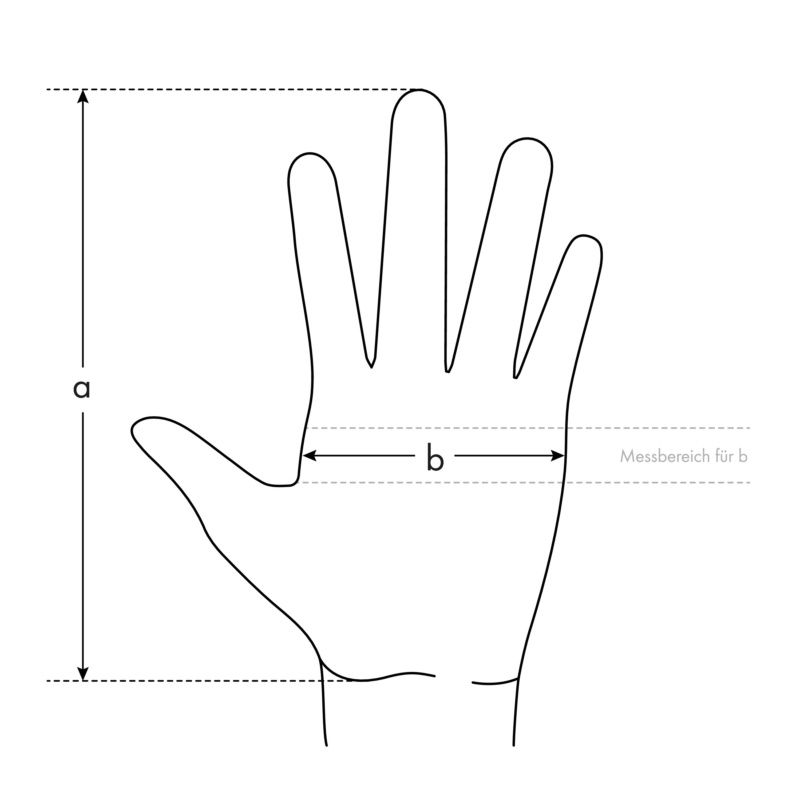

Find the right glove size

Two key variables are relevant for determining the correct glove size:

a) Hand length: Distance between wrist and tip of middle finger

b) Hand circumference: Measured with a measuring tape placed 20 mm above the bend between thumb and index finger.

Measure both sizes and then use the results to determine your hand size:

| Hand size | Hand length in mm | Hand circumference in mm |

|---|---|---|

| 6 | 160 | 152 |

| 7 | 171 | 178 |

| 8 | 182 | 203 |

| 9 | 192 | 229 |

| 10 | 204 | 254 |

| 11 | 215 | 279 |

| 12 | 215 | 304 |

Colour coding system on the glove cuff

A unified colour coding system applies to all gloves in the Würth range that have an edging. Each colour represents a specific size.

They are assigned as follows:

The Adolf Würth GmbH & Co. KG collects and processes the personal data provided in the form in order to process the requested request for you. Please note the mandatory fields in the forms. The legal basis for this processing, the absolutely necessary data, is Art. 6 para. 1 lit. b GDPR, implementation of a pre-contractual measure. The processing of data voluntarily provided by you is carried out on the basis of Art. 6 para. 1 lit. f GDPR. Thereafter, processing is permissible which is necessary to safeguard our legitimate interests. Our legitimate interest is to have contact with you, our customers, to improve our consulting quality and to be able to contact you more easily in case of possible queries. The data collected will only be stored by us for as long as is necessary to process your enquiry and to contact you. They are then deleted.

Supplementary data protection information, in particular regarding your rights to information, correction, deletion, restriction of processing, objection and complaint, can be found in our data protection declaration.